A dummy load is a high power single terminal device intended to terminate a transmission line. They are typically employed to test high power microwave systems at full power capacity.

Mega Industries’ waveguide dummy loads and terminations are designed to fit your application. We manufacture a complete range of high power microwave loads and terminations. The FXR Dummy Load product line includes: super high power, air cooled (finned or unfinned) and water cooled. Each series of our dummy loads provide different objectives. Available in sizes from WR28 to WR650 and covering a frequency range of 1.12 to 40 GHz.

Unfinned

Unfinned Dummy Loads 1.12 – 40 GHz

WE Series

- Extremely Rugged High Power Loads

- High Temperature Refractory Load Elements

- Economic Convection Design

- Available with most Common Flanges

Mega WE series dummy loads are rugged high power units designed to satisfy minimum cost and weight objectives. Models are designed for bands from 1.12 to 40.0 GHz.

The WE loads employ high temperature refractory load elements designed to meet the requirements of MIL-D-3954A. These load elements are in direct contact with the waveguide walls for optimum heat transfer. They can withstand extremely high temperature, temperature gradients and thermal shocks. For additional cooling fins see the WF series.

These loads can be supplied to operate over the full indicated waveguide frequency band. Generally faster delivery and a more efficient unit can be furnished for use over narrower frequency ranges. Always specify your frequency and VSWR requirements.

The table below provides power ratings for each model. The independent average power rating assumes CW operation, and the independent peak power rating assumes negligible average power. The combined average and peak power ratings should be employed together.

Designs to meet special requirements for bandwidth, size, flanges, etc., are available on request.

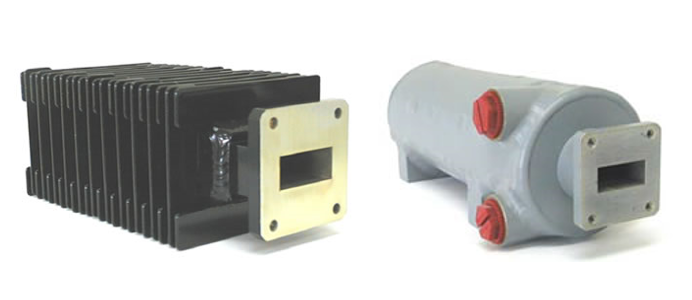

Finned

Finned Dummy Loads 1.12 – 40 GHz

WF Series

- Extremely Rugged High Power Load

- High Temperature Refractory Load Elements

- Transverse Cooling Fins

- Available with most Common Flanges

Mega WF series dummy loads are the commercial equivalent of the standard military DA loads. Models are designed to meet the requirements of MIL-D-3954C in all electrical and mechanical respects for bands from 1.12 to 40.0 GHz.

The WF loads employ transverse cooling fins and high temperature refractory load elements designed to meet the requirements of MIL-D- 3954C. These load elements are in direct contact with the waveguide walls for optimum heat transfer. They can withstand extremely high temperature, temperature gradients and thermal shocks. The WG series is a similar finned design, but with enhanced heat transfer. For lower powers unfinned models may meet the need, see the WE series.

These loads can be supplied to operate over the full indicated waveguide frequency band. Generally faster delivery and a more efficient unit can be furnished for use over narrower frequency ranges. Always specify your frequency and VSWR requirements with any request.

Designs to meet special requirements for bandwidth, size, flanges, etc., are available on request.

Super High Power

Super High Power Dummy Loads 1.12 – 40 GHz

WG Series

- Highest Power Air Cooled Loads

- High Temperature Refractory Load Elements

- Transverse Cooling Fins

- Available with most Common Flanges

Mega WG series dummy loads are designed to offer superior performance that exceeds that offered by the standard military DA loads. Improved fin location, slight physical size alterations, and other enhancements make this increase in performance possible.

The WG loads employ transverse cooling fins and high temperature refractory load elements that are designed to conform to the requirements of MIL-D-3954C. These load elements are in direct contact with the waveguide walls for optimum heat transfer. They can withstand extremely high temperature, temperature gradients and thermal shocks.

These loads can be supplied to operate over the full indicated waveguide frequency band. Generally faster delivery and a more efficient unit can be furnished for use over narrower frequency ranges. Always specify your frequency and VSWR requirements with any request.

Designs to meet special requirements for bandwidth, size, flanges, etc., are available on request.

Power Ratings: The Independent Average Power ratings assume CW operation and the Independent Peak Power ratings assume negligible average power. The Combined Power ratings should be employed together. Forced air cooling is necessary to reach the highest levels listed.

Liquid Cooled High Power

Liquid Cooled High Power Dummy Loads 1.12 – 18.0 GHz

WL Series

- Maximum Power Liquid Cooled Loads

- High Temperature Refractory Load Elements

- Mounts in Any Position

- Available with most Common Flanges

Mega WL series dummy loads are the highest power liquid cooled dry loads available in this product family. They are available in the 1.12 to 18.0 GHz region.

The WL dummy loads employ high temperature refractory load elements designed to meet the requirements of MIL-D-3954C. Load elements are in direct contact with waveguide walls for optimum heat transfer. They can withstand extremely high temperature, temperature gradients, and thermal shocks. They are designed to operate at the rated power without coolant for sufficient time to permit detection and correction of coolant system failure.

The units utilize a cylindrical aluminum, copper or stainless steel cooling jacket. Stiffening ribs are employed for mechanical rigidity, improved heat transfer, and optimum coolant flow. Standard NPT female pipe threads are provided for coolant connections. Coolant flow rates shown are the minimum recommended for proper cooling for peak power values. These units may be mounted in any position.

These loads can be supplied to operate at set frequencies over the full indicated waveguide frequency band. Generally faster delivery and a more efficient unit can be furnished for use over narrower frequency ranges. Always specify your frequency and VSWR requirements.

The table provides power ratings for each model. The independent average power rating assumes CW operation, and the independent peak power rating assumes negligible average power. The combined average and peak power ratings should be employed together.

Power Ratings: The Independent Average Power ratings assume CW operation and the Independent Peak Power ratings assume negligible average power. The Combined Power ratings should be employed together. Additional water flow volumes may be necessary to reach the highest levels listed or if inlet temperatures are above 20 degrees C.

Dummy Loads and Inserts

Dummy Loads and Load Inserts 7.50 – 11.50 GHz

WD and WZ Series

- Extremely Rugged High Power Loads

- High Temperature Refractory Load Elements

Mega WD series dummy loads are low cost, miniaturized units with moderate power handling capacity. Models are designed for bands from 7.50 to 11.50 GHz.

The WD loads employ tapered refractory load elements which are capable of withstanding extremely high temperature. These loads are sometimes used as 1 Watt terminations at ambient temperatures as high as 600°F. They are designed to provide optimum performance over approximately 12% frequency bands. Cover flanges are supplied.

The Mega WZ series consists of the tapered refractory load elements as used in the WD series. They can be cemented by the user into a section of waveguide to meet particular requirements.

The table provides power ratings for each model. Independent average power rating assumes CW operation, and independent peak power rating assumes negligible average power. The combined average and peak power ratings should be employed together.

The FXR Dummy Loads product line, designs and IP were acquired by MEGA Industries from Microlab in 2014. Our loads are designed for rugged, high power use. We aim to satisfy minimum cost and weight objectives.

Mega FXR Dummy Loads are high power single terminal device intended to terminate a transmission line. Three types of dissipative material are employed in Mega Industries’ dummy loads: lossy plastic, refractory ceramic, and liquid. Three methods of heat transfer are employed: free air convection, forced air cooling, and liquid cooling. While FXR Dummy Loads can be supplied to operate over full waveguide bands, generally faster delivery and a more efficient unit can be furnished for use over narrower frequency ranges.

The power rating of FXR Waveguide Dummy Loads is a complex function dependent upon many parameters. Average and peak power, guide pressure, external temperature, guide size, air flow, and availability of auxiliary coolant all play factors in the final power rating of a dummy load. The average and peak powers are interrelated in that the peak power capacity is a function of the operating temperature which in turn is a function of the average power. These are then impacted by the ambient temperature of the cooling medium (air or liquid). The tables on the following pages provide power ratings for each model. The independent average power rating assumes CW operation. The independent peak power rating assumes negligible average power. The typical combined average and peak power ratings should be employed in combination. Our application engineers will readily assist in determining proper loads for a particular application.

Air cooled high power dummy loads have high surface temperatures and must be finished in such a manner as to increase heat transfer. Mega employs a heat resistant black silicone-based paint (>525°C) for most applications, although custom finishes are available for even higher surface temperatures.