Mega was recently featured in an article published by The American Machinist trade magazine.

What is waveguide?

Unless you’re a scientist or microwave engineer, you probably could not care less about waveguides. Most people would have a hard time describing one, but waveguides are both more important and less mysterious than you may realize. If you’ve ever made a telephone from tin cans and string, you’ve made a waveguide. A doctor’s stethoscope is a waveguide, and so is a microwave oven.

As the name indicates, a waveguide is a guide for waves, herding what are normally omnidirectional ripples of sound or light into a coherent stream of useful energy. These may be acoustic waves, radio waves, or in the case of reheated takeout food, microwaves.

This last type of waveguide is what interests Walter Wunderlich, even though the microwaves he’s herding are roughly 100 times more powerful than those propagated by the microwave in the company breakroom.

Wunderlich is executive vice president for Special Projects at Mega Industries LLC in Gorham, Maine. He’s been there since founder Don Paul opened the business in 1989, and has watched the company expand to more than 65 people and 38,000 sq.ft. of manufacturing and office space. Today, Mega Industries supplies high-power microwave transmission equipment to several national research laboratories, including Los Alamos, Oak Ridge, Lawrence Berkeley, and Argonne. It also supplies the European Organization for Nuclear Research (known as CERN) in Switzerland, well known as the site of the Large Hadron Collider.

“Most of our products are for the scientific or military sectors,” said Wunderlich. “We work with the likes of Raytheon and Lockheed Martin on the defense side, along with a large number of domestic and international research institutions. These are the scientists who use particle accelerators like the LHC to investigate the Big Bang, or radio telescopes to listen for extraterrestrial life. And closer to home, we also have a number of industrial clients; Hormel, for example, uses our high-powered RF (radio frequency) waveguides to precook bacon and other foods prior to packaging.”

Riding the wave

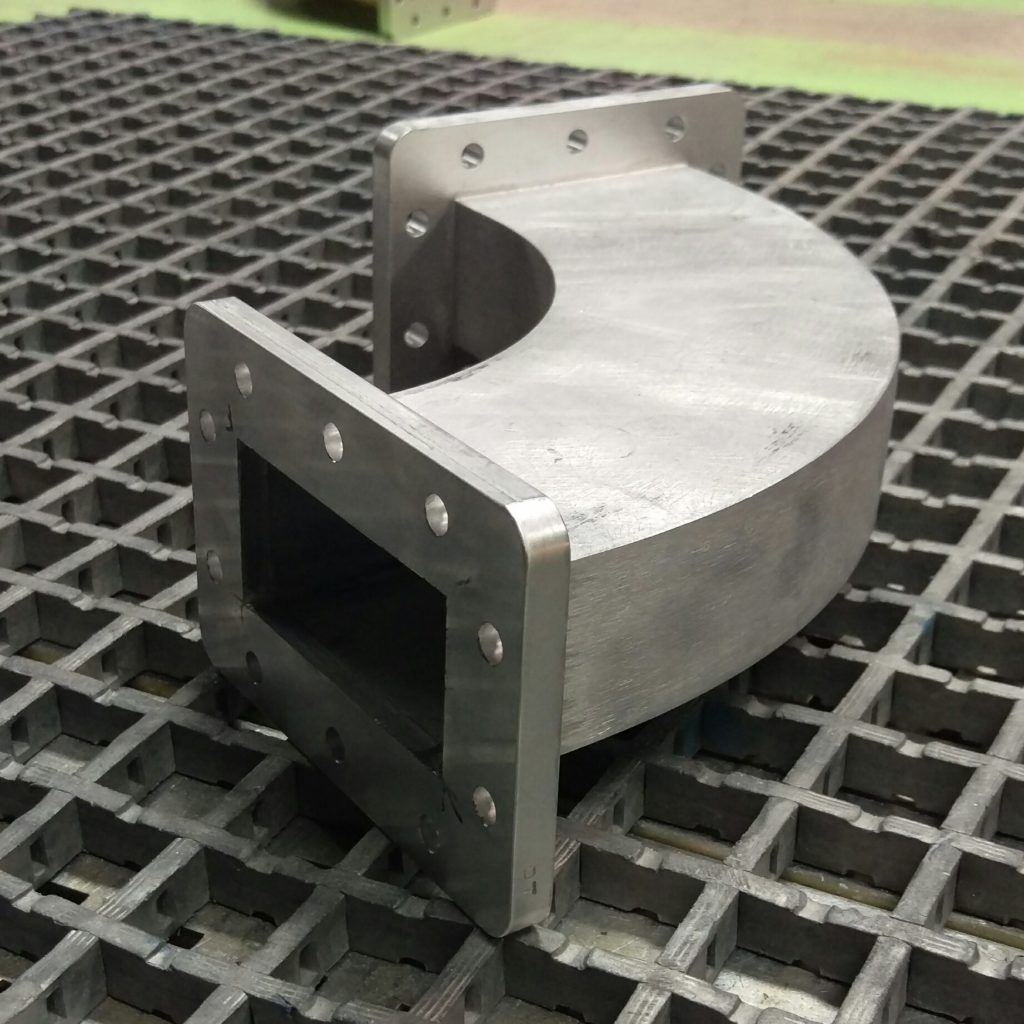

It’s heavy stuff, to be sure, and yet the Mega Industries machine shop is similar to any other well-equipped manufacturing company, with welders, grinders, testing and finishing equipment, and a team of experienced operators.

One of Mega Industries’ key pieces of equipment, used to produce the high-tech components and machinery is a CNC machine center comparable to one found in thousands of shops across North America: a 15-HP, 24-tool Kent USA KVR-4020A, capable of 10,000-rpm.

The Kent KVR series CNC machines are linear way, medium-duty vertical machining centers that combine proven design with advance control technology. Kent’s C-frame and moving-table VMCs are equipped with various spindle and ATC configurations, to match customers’ working requirements.

Wunderlich recalled that the Mega Industries managers decided to purchase a new machining center two years ago: one of their older machines was tired, and it was time for an upgrade.

“Walter reached out to Norman Crepeau, a principal at Machine and Electrical Consultants Inc., and we went to look at a machine at a job shop near here,” recalled machine shop supervisor Mike Ballard.

“One of the first things we noticed about the Kent USA was its construction: Where some of the other machines we’d checked out leaked coolant and appeared to be assembled sloppily, the Kent USA looked like it was built with a lot of attention to detail.”

The KVR-4020A had been pre-wired for a fourthaxis, a standard feature with Kent USA machines, and had spindle chiller and through-the-spindle coolant feature. “The fourth axis was a big deal for us,” Ballard added. “None of our other machines have that capability, and we knew it would increase our flexibility by allowing us to complete more of our parts in a single operation.

“All in all, the KVR fit the bill perfectly,” Ballard said

Hassle-free

After Wunderlich placed an order for a KVR-4020, “the dealer called to tell us the machine had been damaged during shipping,” Ballard said. “I suppose Kent USA could have replaced the dented sheet metal and made it look like new, but that possibility never even came up. They just sent us a new machine, no questions asked,” he added

The KVR has performed better than he expected. Ballard said the rapid traverse rates are roughly twice those of the old machine, with accuracy and metal removal capabilities to match. Also, the control has proven to be more capable, with features that “make it easier to get things done.”

Advanced functionality is important with any machine tool, but reliability is even more important. Since the installation, the KVR has been operating well for two shifts each day, machining aluminum, brass, and stainless components— and there been no unplanned downtime.

“Mike and I have been very pleased with the machine’s dependability,” Wunderlich said. “There’ve been no breakdowns, and I haven’t had to make a single service call on the KVR. I would buy another one in a heartbeat.”

This article was originally published by American Machinist on April 30, 2020.

[…] is the executive vice president for Special Projects at Mega Industries LLC in Gorham, Maine. He’s been there since 1989, when founder Don Paul first opened the doors, and […]